- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2010

- 2009

- 2008

- 2007

- 2006

- 2005

- 2004

- 2003

- 2002

- 2001

- 2000

- 1996

- 1989

- 1985

- 1979

-

Acquisition of the HERMLE milling center with palletizing, wire cutters with palletizing

There have been many investment projects this year that we would like to start using to the full. These are new machines, equipment, software, racks, etc. We expect full use of investments and thus also savings in both time and money in 2020 and beyond. We monitor work that is routine, repetitive, and that can […] -

Implementation of warehouse heating, change of handling equipment

From all our main customers, we received orders for tools and spare parts, as well as projects, including stamping. As you probably know Audi, Seat, VW, BMW, Nissan, Skoda are brands where you can find our products or products that are made on our press tools. We have also been involved in the production of […] -

Acquisition of a wire cutter and two GTX presses

From the planned construction investment projects we managed to successfully implement: and. moving in KV – a new workplace of EDM and grinding b. relocation of the welding shop and establishment of a locksmith workshop c. moving in HV – location of two new presses d. implementation of an automatic feeder for the Schuller press […] -

Construction of a new warehouse, modernization of the entrance and access roads

It is still true that the basis for the quality of a company’s business is to have the right information at the right time and in the right place. Despite all the problems and several months of delay, we finished with the supplier ITeuro upgrade of corporate IS Syteline 7 to a higher version 9. At […] -

Acquisition of 3D measuring devices, five-axis CNC milling machine, CNC grinder

The biggest project of the year was tools and spare parts for our Mexican customer. Thanks to well-set processes and work organization at all levels, we have also managed new Audi, Seat, VW, BMW projects. These are projects mainly for our press shop. We also devoted a lot of time to continuing teamwork on internal […] -

Acquisition of feed lines for presses

The biggest project of the year was the reconstruction of press tools of Turkish origin for the company Magna. This production was new for us and managing it required a lot of effort and dedication of our employees, without whom such a project would not be possible at all. Thanks to well-established processes and the […] -

Construction of the second part of the press shop and modernization of the boiler room – installation of CHP

We managed to successfully implement most of the investment projects we have planned in recent years: We have completed the reconstruction of the boiler room – cogeneration – gas / electricity, in order to reduce the consumption of electricity for heating in the winter months, for which we received confirmation of a full application from […] -

New machinery for testing tools, GO press VORONĚŽ 800t, Construction of a retaining wall

We managed to successfully implement some investment projects that we had planned in previous years in 2012. We extended the retaining wall behind the press shop – the result is an increase in the logistics area in front of the office building We have built a new parking lot We made a GO press 800T […] -

Educational project within the subsidy program Human Resources (subsidies from the EU)

In 2010, we prepared a project for gasification of the boiler room with the possibility of using alternative heating by cogeneration. We also completed the construction of a press with the possibility of drawing an EU subsidy revitalization program. The Voronezh 800 T press was also overhauled. In order to increase the parking area for […] -

The company-wide Infor-Syte Line information system has been introduced

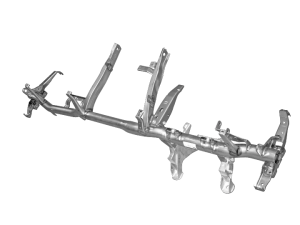

In 2009 ROSTRA introduced a new Infor production program – Syte Line. Manufacturers of discrete and manufacturing processes around the world use Infor® SyteLine locally and in the cloud to simplify and automate their complex manufacturing processes. SyteLine® offers a range of features from advanced material planning and management to finance. Daimler Staukasten project for […] -

Project PSA T75, Acquisition of a welding press and introduction of a new production technology – welding of nuts

Project PSA T75 and welding of nuts. -

Purchase of new machines, increasing the capacity of CNC milling and electro-erosive cutting

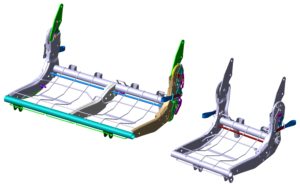

Project of pressing tools and pressing of a part for the company MAGNA – SLW. -

Construction of the first part of the press shop and tool test room

Construction of a new press hall. Projects of production of pressing tools and pressing for the company BENTELER project BMWPL6 / F07. -

Construction of a new assembly hall for the tool shop

Construction of a new assembly hall. Projects of production of pressing tools and pressing for the company BENTELER project BMWPL6. -

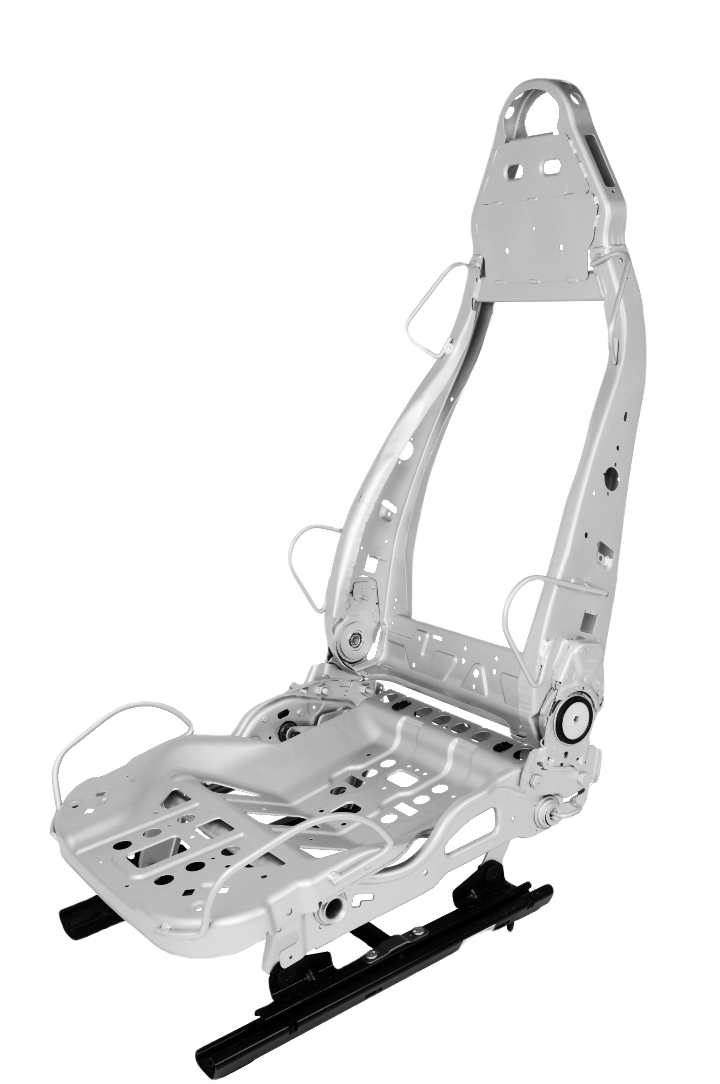

Start of serial pressing for automotive

Parts pressed by our tools can be found in cars of all world brands, including luxury brands BMW, Bentley, Jaguar, Opel, BMW, Volvo. Customer demands are constantly increasing, the current customer requires high quality products delivered in a short time. These requirements place high demands on production management, quality and logistics, as well as on […] -

Project of a new program of gas boilers

Project of a new program of gas boilers for the company MORATOP. For this boiler, we produced molds, pressing tools for sheet metal parts and various jigs for mounting the boiler. At that time, we manufactured and started pressing project holders for “flat screens” in millions. -

Purchase of presses

With its production program, ROSTRA has continued the good tradition of precision engineering production in the Zlín Region. The main program is the production of tools for stamping sheet metal parts, the production of molds for plastic injection and the production of precision parts used in the automotive industry. The second production program is the […] -

Obtaining a quality management system certificate according to ISO 9001: 2000 and ISO / TS 16949

ROSTRA is certified by the ISO 9001 and ISO / TS 16949 quality system, which is required by customers from the automotive industry. We started manufacturing parts for the Opel SuzukiR + and Opel Agila projects – called Rear Axle Pin (Safety Part “D”). The production process began with turning on SAY 48 and SAY63 […] -

Establishment of ROSTRA sro

In 2000, it was decided by the General Meeting of the joint-stock company TMP to sell the plant 05 in Vizovice – the main reason was the shift in production from telecommunications. Among those interested in buying the company, the company ROSTRA sro won the tender, which had a clear idea of maintaining employment, gradual […] -

In the 90s

In the 90s, it was especially important to promote the plant among quality suppliers in the competitive capitalist market. TMP began to gradually reduce the production of connectors for telecommunications, only the production of buses for the American company Keptel USA remained. TMP was awarded by a foreign customer as a flawless supplier. Nevertheless, there […] -

Revolutionary year 1989

“Revolutionary” 90. years meant big changes for the company. In 1991, the CMEA association or the Council for Mutual Economic Assistance was abolished, which was the target market for the products of Telecommunication Assembly Prague (TMP). There were also personnel changes in the plant management. Shortly after the revolution, the company was led by Ing. Josef […] -

Assembly company Prague

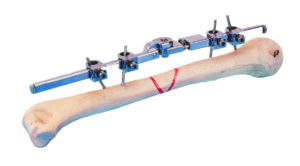

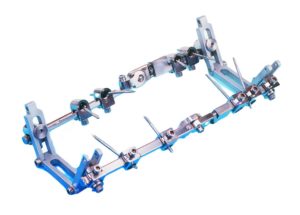

The company TMP, under the leadership of Mr. Matyáš, continued its plans to expand the entire company – both the production of stamping, and e.g. on the production of connecting pliers, quick-release clamps, cable assembly stands and sealing pliers, but also on the development of medical supplies from special materials for the purpose of fixing […] -

TMP Vizovice

ROSTRA continued the tradition of the former TMP-telecommunication assembly plant in Prague, branch plant 05 Vizovice. The establishment of a company in Vizovice with a focus on the development of telecommunications products was promoted and subsequently implemented by a native of Vizovice – Ing. Zdeněk Matyáš (his father was also interested in the development of […]